Lisa Marie - love those - subtlety, balance, harmony.

Keto Krafts/Art - show and chat right here! By JANIE

I wish I was a better carpenter… I can build just about anything but it takes me twice as long. My husband usually politely pushes me out of the way & takes over  I do art & decorate, he builds stuff. It’s a pretty good trade off IMO.

I do art & decorate, he builds stuff. It’s a pretty good trade off IMO.

Agreed, the smaller piece is much more spalted but, honestly, it’s a lot harder to work with because technically, the lighter pieces in there are “rot.”

I have beem looking at a lot of metal art recently. I’d love to see yours!

Nah - mine has the basement and a pool table. I only have 3 bedrooms and the sitting room for my stuff. LOL

Excellent! I’ve seriously considered jettisoning all of the dining room furniture in favor of looms and the required loomy stuff! Shhh  don’t tell my husband!

don’t tell my husband!

Yeah, @brownfat, like @OldDoug said, I missed this when I discovered the thread the other day and started going through it. Very cool!

Is that your design or a RepRap-based design? (Most of the commercial printers are derived from the RepRap concept, so that’s not an insult)

I’ve been thinking of building one myself, but a guy on another forum told me he did a comparison and could buy an Ender3 kit for less than he could get the parts. Still not sure if I build or buy.

I’ve built machine tools - CNC conversion on a couple of milling machines, and a small CNC lathe making it my threading machine - so I have some understanding, but no experience with 3D printers.

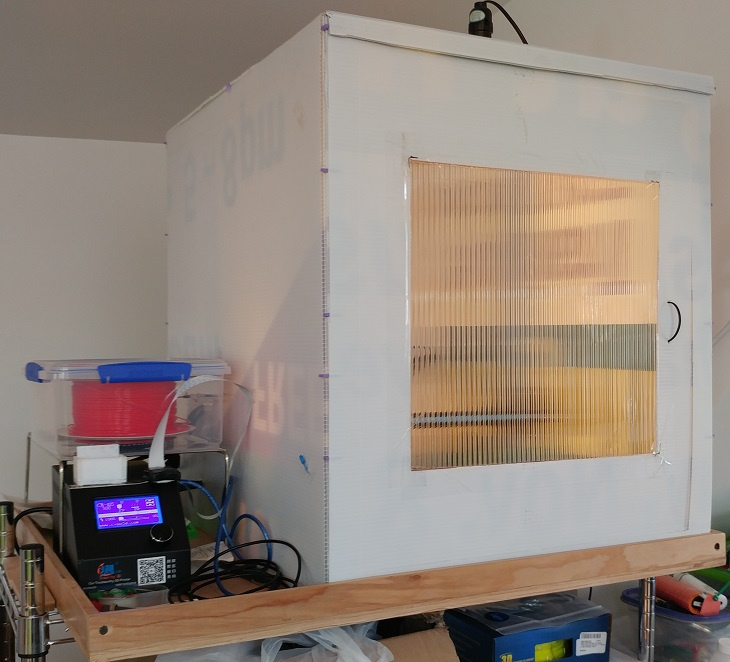

I started with a popular inexpensive large format chinese printer of RepRap’ish design, a creality CR-10, for which there is a large user community and lots of after market parts, accessories and upgrade plans. I used the printer to print many of the parts I’ve used to expand it’s capabilities with new print heads, better heating and cooling, the enclosure and filament dry box, etc. such that it can now print with a wide range of challenging filaments from polycarbonate to TPU.

The downside of my approach is the printer will never be as fast or precise as a top of the line printer or a scratch built one made from premium parts but my total cost has been very small for the capabilities achieved.

I’d love to have some CNC machine tools such as a mill and lathe but don’t have enough room in the basement or permission from my wife to take over more of our living space. At least I’ve got access to some old ones in a rough state of tune at our local makerspace which will have to suffice for now.

The classic trade. The oldest cliche’ is whatever size you get, you’ll inevitably need 1" bigger.

I started with a Micro mill and lathe. My wife actually got me the lathe and got things started. All Sherline. These have a small work envelope, like the mill is roughly 3"x9". The lathe (get the long bed) is 3x 17. In any lathe, length is to make up for the drill chuck and bits or things you might put in the tail stock.

When we started planning for retirement, after a zillion other decisions, we decided to add a “dream shop” onto the house. By no means is the shop the only use for the room, but I do now have a 1HP mill, a Grizzly (G0704 - they seem to be well known), and a bigger lathe, but I still use the Sherlines for the small parts they’re good at.

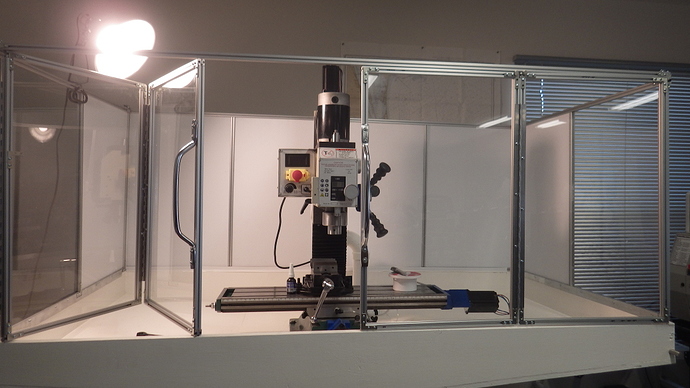

Since this is the internet, and “without pics it didn’t happen”, this is my big mill when the enclosure was almost completed. You can see blue parts and black, long square things (stepper motors). I made all the parts to CNC convert the mill mostly with the Sherlines. Of course, I don’t mean making ballscrews and all; just the mounts.

And here’s a video of a little engine I made with everything in the shop. The engine has a lot of small, “fiddly bits” that were a good match for the Sherlines.

Very pretty work.

I’ve used a Sherline mill and absolutely loved it and wanted one of my own. But then I got access to a Bridgeport and the passion for a Sherline passed. If I had a Sherline I’d use it once in a while for small quick and dirty jobs but it takes so much more time and effort to do things which are easy on a more substantial mill.