This post is by request, if it belongs elsewhere, by all means mods, move it where it ought to be.

I mentioned this cold shirt in a post today about my current fast. Some curiosity was expressed, so I thought I’d try to write up a short post about the first generation of this diy project. I have two versions of this, but the “COLD” shirt lives at my office. This one is more like, a “cool” shirt.

The first gen I’ll discuss here was made to keep me cool while I pursue my hobby welding during the summer. Later I realized that I could make a more powerful one, with a bigger pump, with bigger tubing, and use more ice to go for a shirt that would genuinely make my body work to stay warm. I built this on the hypothesis that surrounding my core with cold would create a caloric load, and work toward increasing the activation of my brown adipose tissue, as well as putting additional caloric load on my body as a whole. The term I’ve seen used is “cold thermogenesis”.

I’m hoping my adding of images works here. If it does, I’ll explain what you’re seeing in each image.

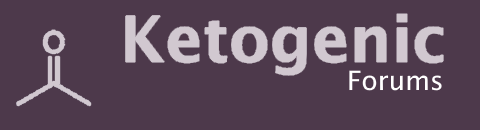

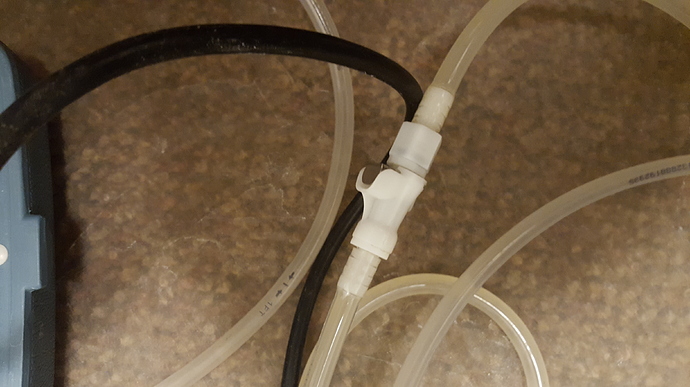

The shirt has metal connectors. This was a mistake, as my adding salt and vinegar to the water mix to lower the temp, and deal with my hard water here, did a number on the metal, and you can see there is a bit of rust staining on the tubing around the connector. This does not affect the function, and I suspect I will shrink out of the shirt long before it matters. The silver colored air hose connector is the right size to attach to the gen 2 tubing, I tested with the gen 1 pump, but found it too anemic for my purposes. Pics of the gen 2 pump tomorrow.

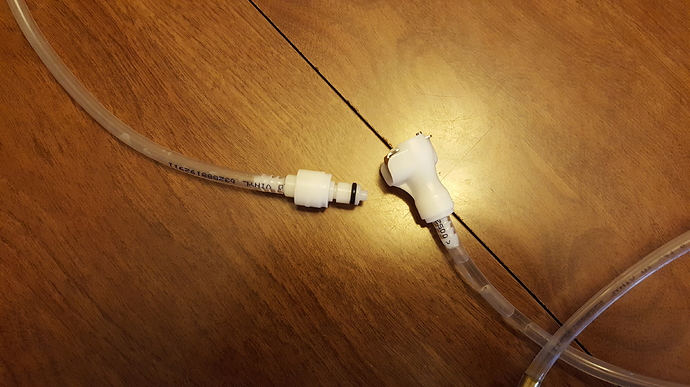

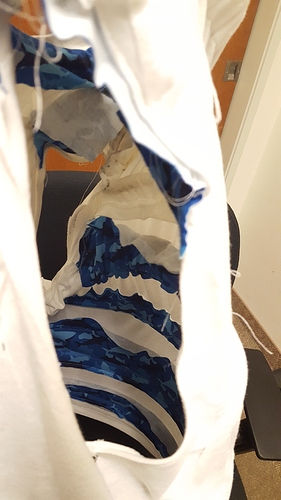

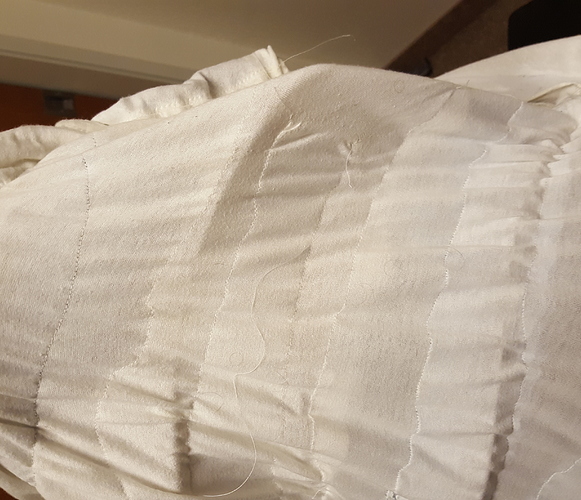

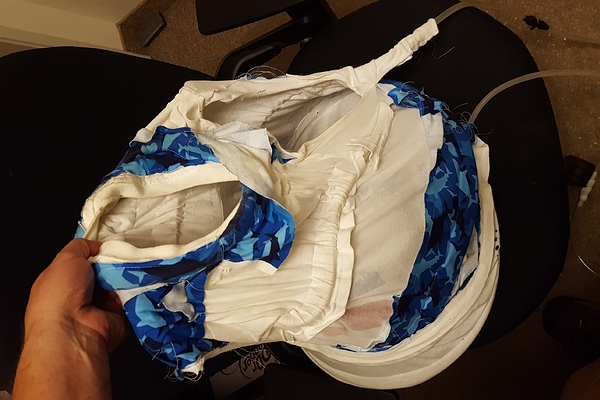

The whole setup minus the tank.

The shirt side connectors, disconnected. Rust stains visible.

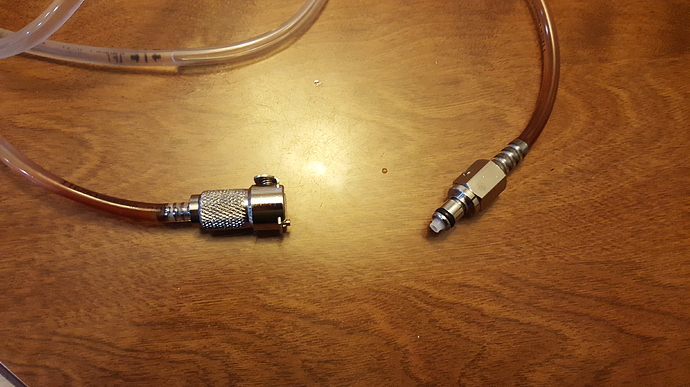

The plastic dry break connectors disconnected.

The pump, hooked to itself. The white dry break connectors hooked up to each other. Both needle valves in place.

This is the smallest pond or fountain pump sold by Harbor Freight (a US company that sells cheap imported stuff).

This is how the connectors look when connected to each other, hooking the shirt into the pump water circuit.

This is the shirt running right now, just using my sous vide water oven as a water tank. The final valve is visible here, in the open position.

The shirt still running, with the tube pulled out so you can see the low flow rate.

Regarding the second iteration of this shirt. Its at work, so I’ll have to take some pictures tomorrow.

Teaser about gen 2 shirt:

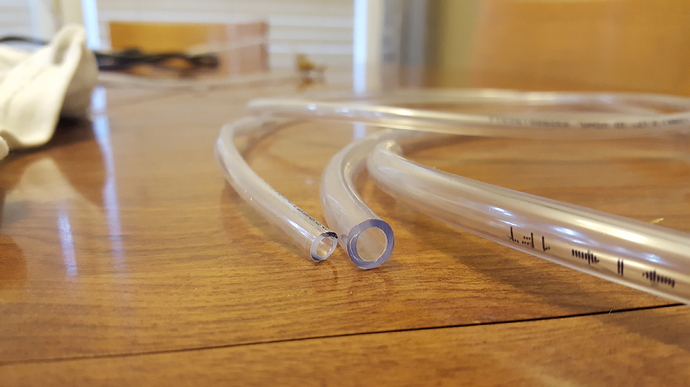

This is the comparison of the two tubing types. The smaller is the gen 1 tubing, with a 1/4" OD (outside diameter). The larger is the second gen tubing, with an ID (inside diameter)of 1/4" and an OD of 3/8".

I’ll be happy to answer questions about this iteration. I’ll post about the gen 2 tomorrow, and probably add the things I would do differently if I made a gen 3.

Keep us updated with the build progress.

Keep us updated with the build progress.